- Industry News

- 392

Beyond "Hardness": Decoding New Trends in Pick Technology for Intelligent & Efficient Coal Mining

Under the "Dual Carbon" (carbon peak and carbon neutrality) targets, the role of coal as a "ballast stone" for energy security is increasingly prominent. Safe, intelligent, and efficient coal extraction has become a key focus for the industry. The humble mining pick, though small, sees its technological iteration directly impacting mining efficiency, operational costs, and the level of intelligent automation.

Xinda understands that the traditional "brute force" approach is no longer sufficient for complex geological conditions. The development of pick technology has long moved beyond mere "hardness," focusing more on technological innovation, customization capabilities, and its contribution to cost reduction and efficiency gains in the entire excavation system.

I. The Traditional "Hardness": Challenges and Bottlenecks of Wear ResistanceTraditionally, mining picks have been primarily evaluated on "hardness" and "wear resistance." However, as mining operations delve deeper and encounter more complex geological conditions (such as high gas content, hard roof strata, and rock interbeds/dirt bands), a singular focus on high hardness often leads to pick chipping and breakage. This not only results in time-consuming and laborious replacements and operational downtime but also significantly increases pick consumption per ton of coal.

II. Xinda's Innovation: Super Wear-Resistant Technology, Reshaping the Value of PicksDirectly addressing these pain points, Xinda, driven by a philosophy of "striving for excellence and meticulously perfecting every detail," has invested millions in R&D to develop its "Super Wear-Resistant Picks," achieving a revolutionary breakthrough. The core innovations include:

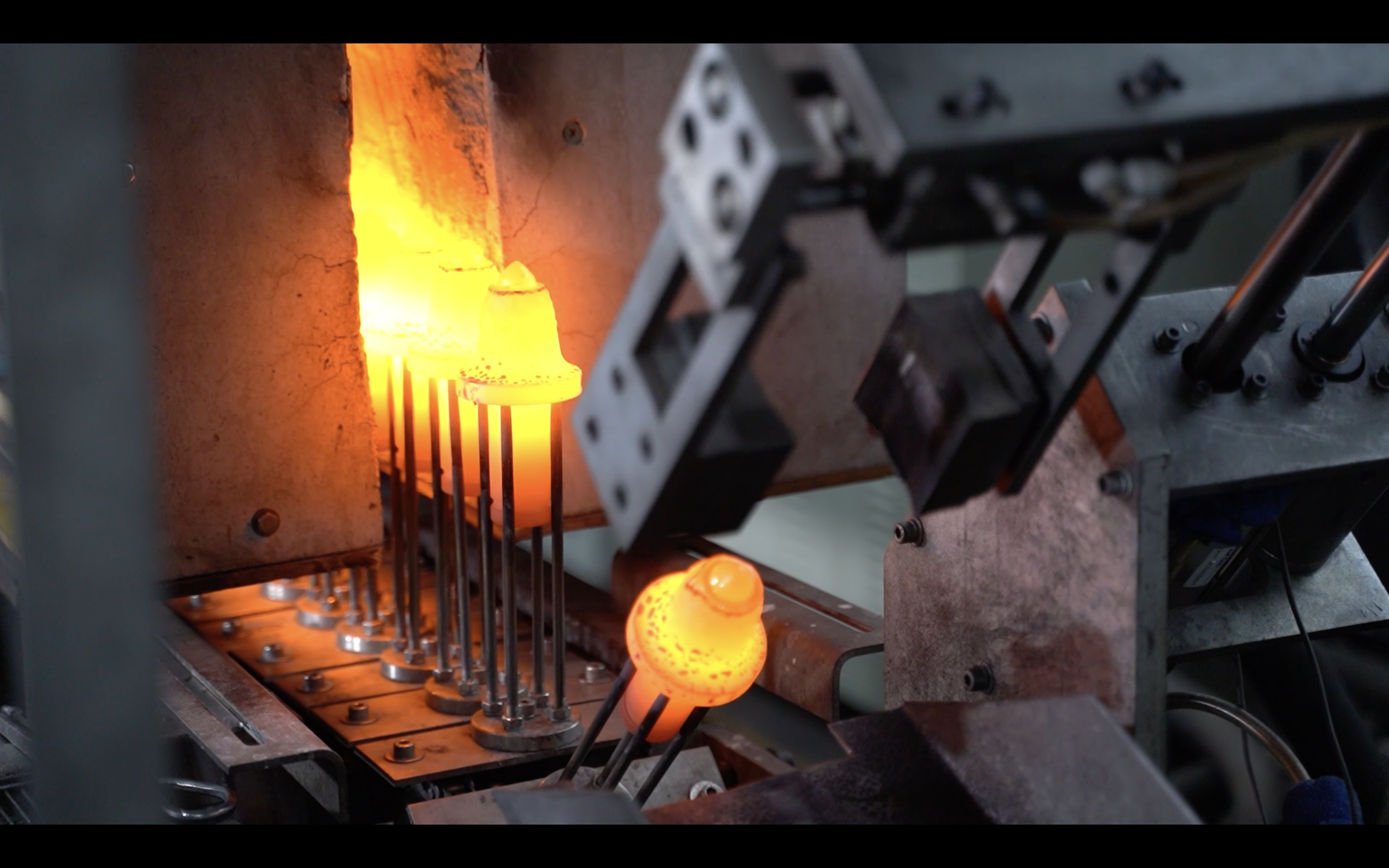

Revolutionary Material Formulation: Optimized alloy element ratios combined with specialized heat treatment processes ensure high hardness in the pick tip while significantly enhancing its toughness and impact resistance.

Advanced Welding Process: Utilizing internationally leading brazing technology, we ensure a dense and robust bond between the alloy tip and the pick body, drastically reducing tip detachment.

Refined Structural Design: The geometric shape of the pick has been optimized. The alloy tip features a frustum (truncated pyramid) design, promoting more even stress distribution during cutting, slowing down wear, and boosting excavation efficiency.

Significant Field Test Results: Xinda's super wear-resistant picks have demonstrated an average reduction in pick consumption rates by 30%-50% and an increase in service life by 1 to 1.5 times across multiple major mining bureaus and engineering projects. For instance, under the challenging F8 fault zone conditions in a large coal mine in Xinjiang, Xinda's super wear-resistant picks achieved an average consumption of only 3 picks per day, with a service life increase of up to 150%! III. The "Intelligent" Trend: Customization and Smart Solutions Empowering EfficiencyXinda believes that the future of pick technology will increasingly focus on:

III. The "Intelligent" Trend: Customization and Smart Solutions Empowering EfficiencyXinda believes that the future of pick technology will increasingly focus on:

Condition-Specific Customization: Tailored to varying coal seam hardness, abrasiveness, and the presence of rock interbeds, Xinda offers "bespoke" solutions – from material selection and pick design to heat treatment processes – truly ensuring "the right steel for the right job."

Data-Driven Optimization: Xinda has collaborated with Central South University to establish a comprehensive rock database, already populated with parameters from numerous rock strata samples. Clients simply need to provide rock samples or on-site data, and Xinda's technical team can leverage intelligent algorithms to accurately match pick models, achieving over 90% accuracy in pick consumption prediction.

IV. Xinda's Philosophy: Competing on Value, Not Price, for Mutual SuccessIn a fiercely competitive industry, many enterprises get caught in price wars. However, Xinda steadfastly believes that true competitiveness stems from superior quality and customer value. We are committed to:

Relentless Focus on Materials: Selecting only high-quality alloy raw materials.

Relentless Focus on Processes: Pursuing excellence in every manufacturing stage.

Relentless Focus on Quality: Implementing a comprehensive quality control and testing system.

Relentless Focus on Service: Providing professional technical consultation and after-sales support.

We choose to "compete on value," driving innovation and service upgrades to help our clients conquer even the toughest geological conditions, thereby maximizing their excavation efficiency and optimizing operational costs.

Conclusion:Though small, mining picks carry significant responsibility. Xinda is committed to leveraging its leading super wear-resistant technology, professional customization services, and an unwavering pursuit of quality and value. We aim to join hands with coal mining enterprises to collectively advance intelligent and efficient mining technologies, contributing "Xinda's strength" to ensure national and global energy security.

Conclusion:Though small, mining picks carry significant responsibility. Xinda is committed to leveraging its leading super wear-resistant technology, professional customization services, and an unwavering pursuit of quality and value. We aim to join hands with coal mining enterprises to collectively advance intelligent and efficient mining technologies, contributing "Xinda's strength" to ensure national and global energy security.